Overview

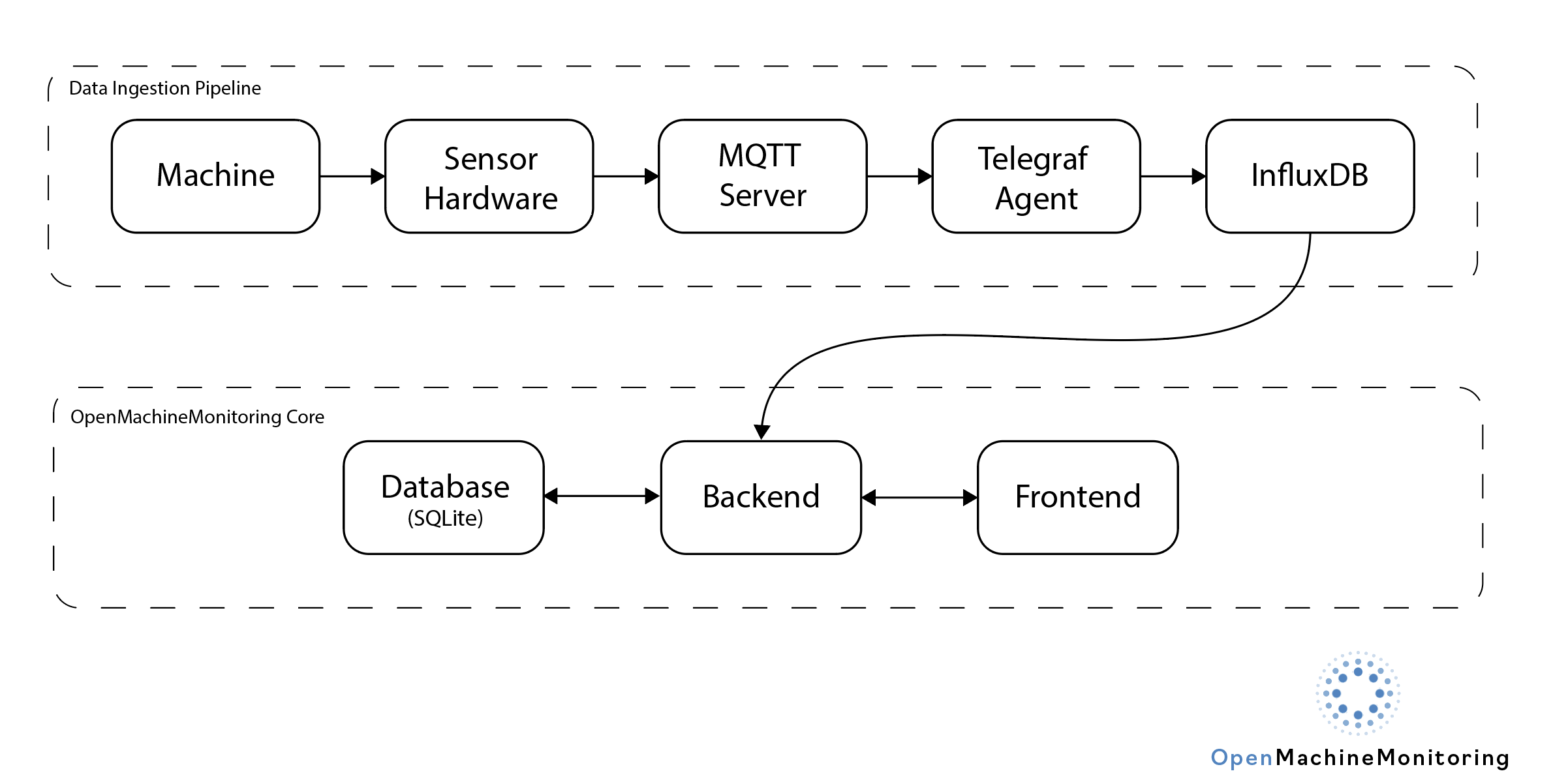

OpenMachineMonitoring is a lightweight, extensible, open-source platform for collecting, visualising, and analysing machine utilisation data.

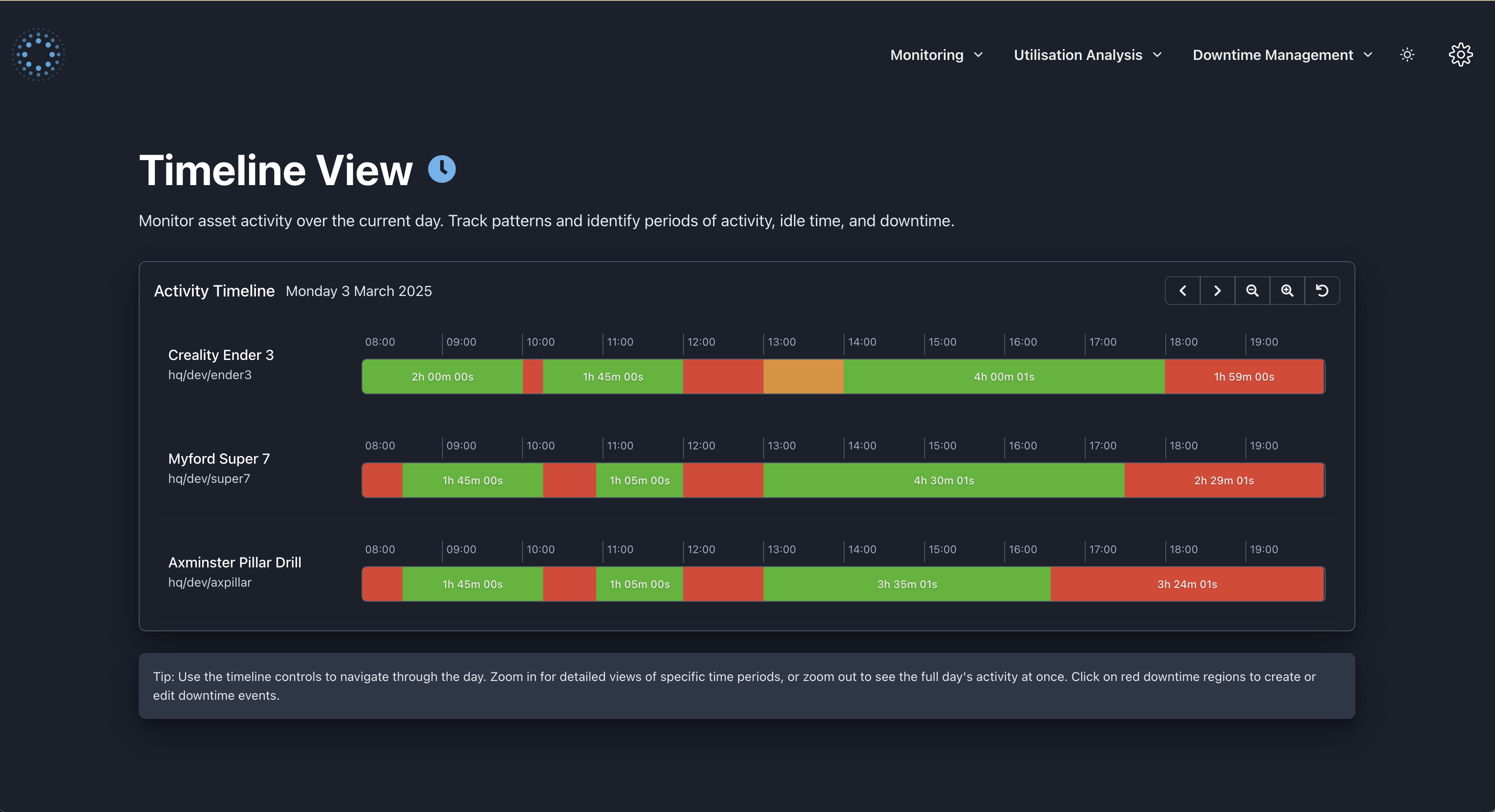

UI showing machine utilisation over the course of a day

Key Features

- Data collection using off-the-shelf current clamp sensors

- MQTT support for easy integration and expandability

- Asset view showing all of the machines currently connected and their statuses

- Timeline view showing different periods of activity over the current day

- Weekly view showing the daily activity of each machine over the current week

- Calendar view showing daily activity over the year

- Comparison view to compare uptime across connected assets

- Ranked view showing all assets in order of utilisation

- Downtime events to explain periods of inactivity with a log and stats view.